3D Laser Welding and Cutting

Always attentive to market needs and continuous technological progress, Artil has introduced 3D laser welding and cutting within its laser department for years, consolidating its role as a leading company in sheet metal processing for third parties. This strategic choice arises from the desire to offer innovative and high-precision solutions, responding to increasingly complex customer requests.

Innovation and Precision in Metalworking

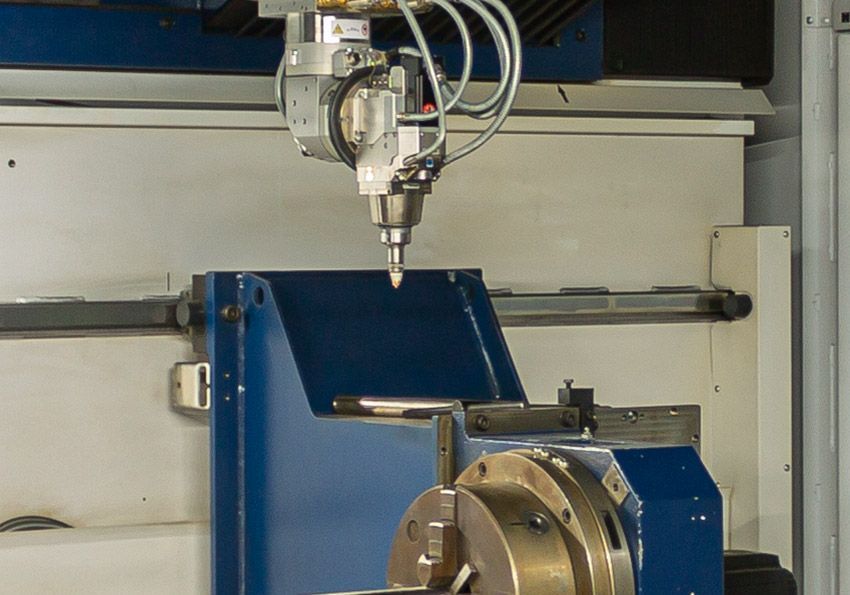

The heart of the 3D laser welding department is the 4000-watt TruLaserCell 7040 system. This cutting-edge machine is designed to deliver excellent performance, with specifications that make it ideal for a wide range of applications:

- Working range: 1500x3000 mm

- Maximum workable thicknesses: up to 5 mm for stainless steel and iron

- Three-dimensional versatility: allows cutting and welding on complex parts, with customised geometries

The TruLaserCell 7040 stands out for its ability to combine cutting and three-dimensional welding in a single process, offering impeccable results in terms of precision and reliability.

3D Laser Cutting

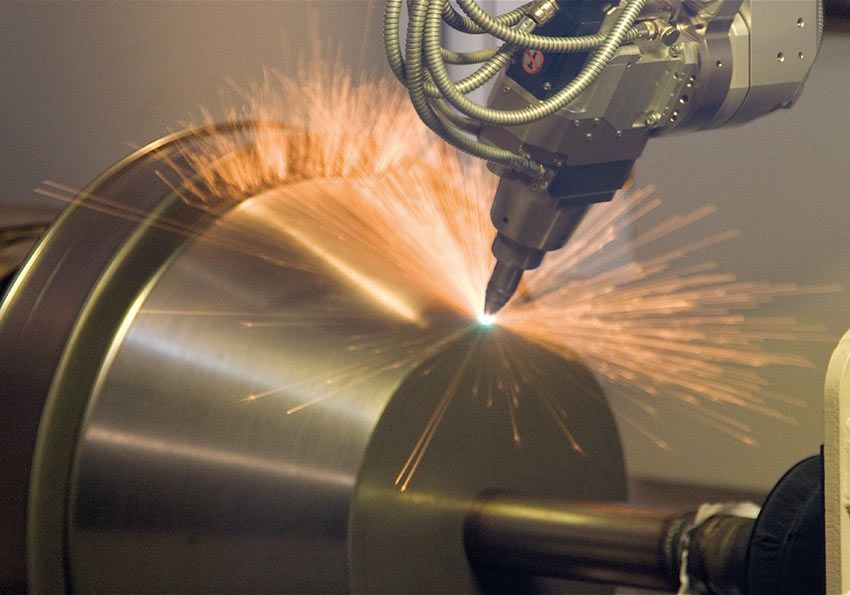

3D Welding

The Advantages of 3D Laser Welding

Extreme precision:

The three-dimensional laser guarantees superior quality in welding, with impeccable finishes and no burrs.

Design versatility:

It is possible to work on complex and three-dimensional shapes, creating unique and personalised details.

Production times:

Thanks to the combination of cutting and welding in a single process, production times are optimised.

Energy efficiency:

The 3D laser uses energy in a targeted way, reducing waste and operating costs.

Laser Welding Applications

3D laser welding is used in many sectors thanks to its ability to adapt to complex and customised processes. Among the main areas of application:

- Automotive: structural components and precision parts.

- Furnishings: creation of unique details and innovative designs.

- Medical industry: high-precision welding for specialist equipment.

- Agricultural sector: parts and structures for robust and reliable machinery.

- Lighting:

custom supports and structures for lighting systems.

Why Choose Artil for 3D Laser Welding?

Thanks to its long experience in the sector and the use of cutting-edge technologies such as the TruLaserCell 7040, Artil is able to offer a complete service, which combines technical expertise and innovation. Each project is followed with the utmost attention, guaranteeing tailor-made solutions that respect the specific requests of the customer.

By relying on Artil for 3D laser welding, you choose a reliable and cutting-edge partner, capable of transforming every idea into a top-quality product. Contact us today to find out how we can support your projects!